About a year back I published a positive review for the Spud Inc Econo Lat & Tricep Pulley. I praised it for its ease of use, versatility, and low price. I even went so far as to refer to it as one of the best garage gym accessories on the market for under $100.

Well you will be happy to know that my opinion of the Spud Econo Pulley has not changed. It’s still just as functional, convenient, and almost as affordable as the day I published my original review. As a matter of fact my own Spud pulley gets used multiple times each week, and I cannot think of any other gym accessory that’s not only this inexpensive, but also used so frequently.

So why am I writing about it again? Because my original review didn’t include any information about durability or the life expectancy of the product, and as it turns out those two things merit some discussion. Why? Because in the year or two this product has been available we have learned that despite the overwhelming number of pros, the product as a whole is still not totally perfect. It has a tendency to show unnecessary signs of early wear and tear for those who actually use the product on a regular basis.

In this article I’m going to explain what the issue with the Spud Econo Pulley is, how you can identify if it’s happening to your Spud system, and how you can fix it. I’ll also give you some ideas on how you can create your own version of this product from scratch – a version that will not only be far less susceptible to wear and tear, but that will also be totally customized to your gym (that is, your rack).

The Issue

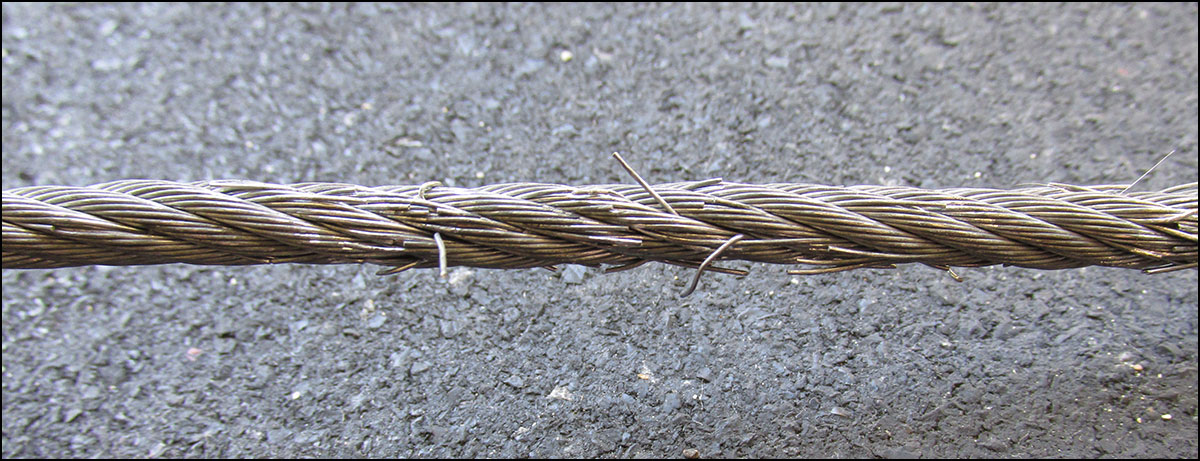

The problem with the Spud Inc Econo Pulley is the cable itself. It’s a ¼”-diameter, 9×17 galvanized steel cable with no protective vinyl coating (image below, left). While this cable does have plenty of load capacity for this application, it cannot handle being pulled through the near 180-degree bend of the small 2½” pulley over and over again. It tolerates it for a while, obviously, but with no protective coating to insulate the steel cable and keep it separated from the steel pulley, the cable eventually begins to fray.

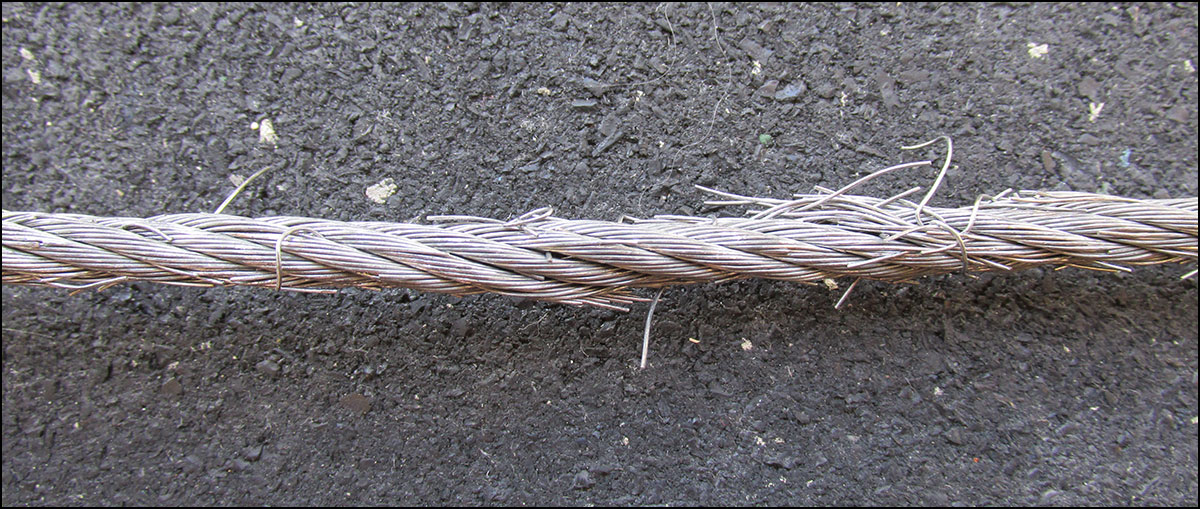

At first it’s a fray or two, then the next thing you know you have a dozen or more – all of which can be found in the section of cable that is regularly dragged through the pulley. How quickly you go from one fray to dozens depends on the amount of weight you are working with and the frequency in which you use the product, but regardless of when it happens you’ll learn that after enough individual wires break the whole cable begins to deteriorate quickly.

An example of moderate fraying. Definitely more than just a couple torn wires, but the cable still has some use left in it before it becomes useless. Keep an eye on it, and watch those fingers.

An example excessive cable fraying. Obviously this cable needs to be discarded and replaced. Even one more set with this cable could be disastrous. Sadly, this cable isn’t even very old.

To be fair, you usually get many months of use before that first wire breaks, and you should get many more months of reliable use even after that happens. You will however need to handle your cable with much more care once you get a fray, as running your hand into one of those stray, protruding wires hurts like a sonofabitch. Any of you who have had the Spud system for a while now know exactly what I’m talking about.

Interestingly enough, Spud’s strap components are indestructible. I wouldn’t be surprised if the looping strap and tricep attachment outlived me. Really the product is great save for the included cable, and I dare say that if Spud Inc included a 1/4″-diameter vinyl coated steel cable instead of the sheathless galvanized cable, the product could very well be considered perfect.

The Solution

The first thing you should do when you become concerned with the condition and safety to your Spud cable is request a replacement directly from Spud Inc; especially if you’ve had the product for less than a year. Ideally you’d want to replace it with a vinyl-coated cable rather than the same junky cable again, but this solution is 100% free so why not give that a shot. Here is Spud’s contact information:

spudincstraps@gmail.com1-803-788-2852

I’ve come across a couple accounts of people managing to get a hassle-free replacement from Spud, but don’t get excited yet. I attempted to contact Spud about the damage to my cable multiple times, but sadly I never heard back. Now I’ve never had to contact Spud Inc before so I don’t know if they have garbage customer service all the time, or if they are just sick of replacing cables, but either way I was unable to get a replacement from them (and shame on them for not even replying). Don’t let my experience stop you from trying though.

When it’s all said and done, if you are still unable to secure a replacement cable from Spud then you will need to do one of two things: buy the whole product over again (not ideal), or simply buy a replacement cable elsewhere; which I’ll get into next.

Spud-Free Cable Replacement

You have a couple options when it comes to replacing that cable on your own. You can buy ¼” vinyl-coated 7×19 cable by-the-foot at the hardware store along with the thimbles and clips and make your own cable, or you can order a custom cable from a gym supply/repair company. Making your own cable is far less expensive than having it made for you (about $15 to replicate the Spud cable length by doing it yourself), but when it’s made at a gym supply company the ends will be crimped professionally (image below, left) instead of bolted together with clips (right).

I priced custom cables from multiple sources, and the least expensive I found was from National Gym Supply. At $50 it still wasn’t nearly as cheap as making my own but I preferred the simplicity over cost in this case (I also didn’t want the sharp ends of the cable exposed on my cable). Oddly enough National Gym Supply was still $30-$40 less than other quotes I was getting (which is ridiculous), but who knows maybe you can find it for even less than I paid.

My black, vinyl replacement cable from National Gym Supply. Expensive, but easy. Also that vinyl moving through the pulley is so smooth – zero friction.

I know having to shell out any additional money on a product you’ve already paid for sucks, but there is a bright side. I’ve seen dozens of complaints in reviews and on discussion boards about the default length of the included Spud Inc cable; about it being too long or too short. Well making or ordering a replacement cable gives you the opportunity to adjust that length to your liking. Silver lining, right?

Build Your Own Cable System

Whether you’re starting from scratch or you need to replace a random component of your existing pulley system, here are some ideas.

The Pulley

Unless you’re permanently installing the pulley somewhere there’s no reason not to use the same swivel-style pulley that’s included with the Spud system; a 2½” swivel eye snatch block for ¼” cables. It costs about $12 and you can see it here. While this 2½” pulley will get the job done, you might consider upgrading to the 3″ diameter version of the same pulley here – it’s only a couple bucks more. Even though an extra half inch doesn’t seem like much, any increase in diameter lessens the stress put on the cable as it travels around the pulley wheel, and that’s good.

Attaching the Pulley

So now how do you attach your new pulley to the rack? The strap that is used to attach the Spud pulley to the rack is actually sewn together after being looped through the eyelet of the pulley, so unfortunately you can’t use/re-use that. One option for those of you who have a crossbeam where you intend to use the pulley is the Rogue Shackle. This is probably about the easiest solution possible, but most standard racks have a pull-up bar towards the entry of the rack, not a crossbeam – so this won’t be very helpful.

** There are three versions of the shackle. One for 2×3 racks, one for 3×3 racks, and one for Monster 3×3 racks. Be sure to buy the correct one. **

Worth mentioning is that anyone with a shrimp trawler on their rack can also use the Rogue Shackle (you can actually see one at the end of the trawler pictured below). Trawlers are a great place for a pulley system since everything is off to the side and out of the way. Spotter arms would work much the same way, but I doubt you could attach a spotter high enough because of all the rack assembly bolts at the top of the uprights. Maybe though.

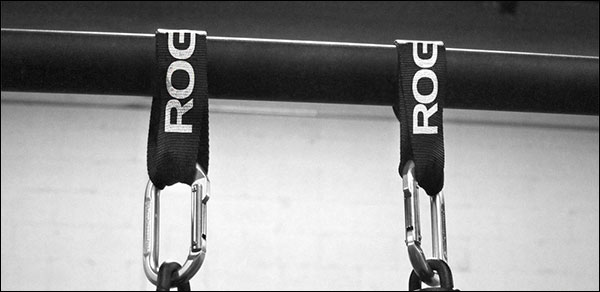

Another option would be the Rogue Strap and Carabiner Set. These are basically short ring straps with carabiners used to attach the various grip/pull-up accessories that Rogue offers. They are sold in pairs which is kind of annoying, but since you’ll have two you may as well just double up for the extra security and piece of mind. And in case you’re wondering, Rogue assured me these are more than strong enough for this application – I asked.

Of course these are just a couple of ideas. There are all kinds of clever ways to temporarily and permanently attach a pulley to your rack, and there are countless discussions on bodybuilding.com and many videos on YouTube with ideas of what has worked for others.

The Loading Pin

You can order the same 18″ strap loading pin that comes standard with the Econo Pulley direct from Spud Inc for $37 (or a 12″ version for $34). You can also purchase a 12″ steel loading pin from Rogue Fitness for only $24.50. Alternatively, you could DIY a loading pin with hardware store components for less than either of these if you were so inclined.

For what it’s worth, I see no real advantage to an 18″ long loading pin versus a 12″. I mean, who is loading plates 18″ deep on their pulley system? Matter of fact, with a standard 90″ high rack you will probably find the 18″ loading pin + the ~76″ long cable to be too long. I certainly do. It’s just something to think about as you put your system together. Clearly its a non-issue if you already own the 18″ Spud loading pin – just keep using that.

Lat & Tricep Attachments

The world is your oyster when it comes to attachments. I touch on it a bit in this article, but you probably already know which attachments you’ll need if you don’t have them already. The only downside to totally building out your own system is that you don’t get Spud’s nylon tricep attachment – it’s pretty versatile and badass.

Have you DIY’d your own pulley system or have you modified or repaired your Spud Inc Econo Pulley using a different method? or completely different hardware? Share with us what has worked for you.

I’d suggest getting a hand-pumped-hydraulic cable crimper from Harbor Freight if you want to build your own cables. The crimp fittings are usually available where cable is sold, and they are quite a bit less clunky and easier to use than the bolt-on cable clamps if you have the tool, which is fairly inexpensive if one is doing a few of these.

Here’s a link to that tool: http://www.harborfreight.com/hydraulic-wire-crimping-tool-66150.html

It goes for about $30 when on sale in the “Insider’s Club”, which is worth joining if you buy from them often. Their print ads usually have a 1-item 20% coupon that would make it about $44 without joining the club

I dunno lol, crimping electrical wire seems pretty different than crimping a load-bearing 1/4″ diameter cable . This is what they use normally for those aluminum hourglass sleeves: http://www.e-rigging.com/economy-five-sixteenths-inch-cable-cutter. Well, I’m sure there is an industrial version of this as well, but this is the economy route. Also this price is probably high but it was an easy to find example.

It’s supposed to crimp up to O-AWG wiring butt connectors — and O-AWG is .32 wire. Those butt connectors for large gauge wire look a whole lot like the cable crimps, the jaws look to be the same shape at first glance, and a little hydraulic cylinder like that can develop a lot of force, probably substantially more that at least I could create with the lock-cutter-style crimping tools — that said, I haven’t used the tool on cable crimps yet (got it to try there but first for a car I’m rewiring). Thanks for the link, though.

Nice update to your original post.

I just ordered this piece and am wondering if there’s anything to be done to the original cable to prolong /beef up the stressed area?

That I don’t know. I doubt it. Maybe someone will know something that I don’t though

I would add that the 18″ pin is a must if you wish to do lat pulldowns with thicker bumper plates. I use Rogue Echo bumpers and can load 5 45s on the 18″, I would only be able to get 3 on the 12″. I only really load that much weight for pulldowns (using your idea for the leg hold down crossmember), so if you have narrower plates or don’t care about heavy pulldowns this wouldn’t be an issue.

I found a nice side benefit for your leg brace idea as well: I attached a pulley to it, ran a 5′ cable (just long enough to reach on my setup) to it from the top cable, and now it works great for seated rows sitting on a flat bench. If you get the cable length correct you can push your feet against the crossmember and get full range of motion.

That’s a pretty good idea.

Also good point about the loading pin. I may revise that section completely.

I had Yukon Fitness build me a custom cable for $35 shipped. It’s 1/8″ cable vinyl coated to 3/16″, and it’s the perfect length for my short rack.

When you bought your cable from Yukon Fitness was the two ends of the cable the Marine Eye End Zinc (1/2″ hole) or did you order a different end type. If it was different, can you let me know what the end type was.

You mentioned liking the cable to have a clean look. I asked around at work and actually found someone with a swaging tool. I borrowed it. Got the rest of the parts at the box store and have a cable that looks just like the one you have pictured for less than $7. It’s not black, but I’ll take the clear coating for the price savings.

I just stumbled across the Valor Fitness PY-1 Pulley Cable Station –

http://valorfitness-com.3dcartstores.com/PY-1-Pulley-Cable-Station_p_393.html

MSRP for the PY-1 kit is $69.00 and can be found cheaper on eBay, as expected.

Unfortunately, the straps appear to be less robust vs. the Spud/Rogue straps. The Valor Fitness PY-1 also employs a 2″ pulley (from what I can determine from its ‘line art link’ as provided on the product’s page.) However, it does appear to come with nice-looking, sheathed 75″ long cable – perhaps the cable can be ordered separately? Valor Fitness is located in Seminole, FL.

For potential pulleys, cables and parts for your own DIY projects, be sure to search eBay for “Bowflex pulley” and similar search terms, as there are quite a few Sellers with 3-4″ pulleys and related parts.

I purchased the Rogue Loading Pin and Rogue Shackle for my setup and then a DIY cable & pulley from the Home Depot. After use, though, the pulley from HD was just garbage, and I’ve seen the Spud Pulley isn’t that great, either. IMO, the Spud system is way overpriced, hence, the DIY w/ quality components.

I found a fitness system pulley from Atlantis Fitness http://www.exercise-equipment-parts.com/3-inch-pulley-block.html and it’s made a world of difference. Smooth as butter for $20.

If you’re interested, you can see some pics of my setup on Rogue’s site under the reviews on how I use my pulley.

http://www.roguefitness.com/rogue-loading-pin (review by randallwise)

http://www.roguefitness.com/r3-infinity-rig-add-on

Is there a load capacity anywhere on that pulley? I don’t see one in the product description.

The Sorinex loading pin runs $25.00 (approximately 16″ long) –

https://sorinex.com/product/sorinex-mighty-mitts-loading-pin/

In the reviews for the Spud Inc pulley system on Rogue’s site someone suggested applying flex seal (a liquid rubber sealant coating) to the cable –

Here’s the product site: https://www.flexsealproducts.com/product/stop-leaks/

Any thoughts?

I don’t really know. The pulley shouldn’t squeak. If it does, just a drop of oil will fix that.

Maybe the sealant will help with cable life, maybe it’s gimmicky. Will cost you $23 to find out though. Maybe someone else will chime in cause I just don’t know, sorry.

I have the SML-2 Squat Rack Would you recommend a different length on the cable?

Starting from scratch here :)

You just have to kind of estimate what would work best for your height and the exercises you plan to use the system for. Loading pin + carabiners + cable + attachment. Where do you want the attachment to be for a starting position, you know? I wish there was an easier answer.

Thanks a lot for the info. In the link that you provided to national gym supply did you order the “black cable thin” or the “black cable thick”?

It’s the thick.

Receipt reads: Cable #1 – Mar 08, 2017 76 0″ Cable 3/16″ Black Coated to 1/4″(per ft) End C (for 3/16″-1/4″ cable) End C (for 3/16″-1/4″ cable)

Could you tell me when you ordered the 3/16-1/4 thick Black vinyl covered Cable, what was the type of end for the cable you chose. There are many choices on the form we must fill out and I wasn’t sure which one would be the correct one to order. Any information you can provide would be appreciated.

My receipt calls it End C, Oval Sleeve. It’s basically the same thing that’s already on the default pulley cable.

Where do you get carabiners if you build your own?

Amazon, hardware store, climbing stores. You gotta look at the ratings – don’t buy anything too small. 3/8″ thick is pretty standard. Wouldn’t go any smaller than that.

Do you find that the vinyl coated cable is immune to fraying? Or does it just delay the inevitable, that has happened to the non coated version? (Assuming proper usage and oiling of pulleys).

Ken I don’t know how I missed this, but it looks like I did. I apologize.

The vinyl cable is a wearable item just like the non-coated cable, but the vinyl coated will last infinitely longer. There is almost no real cost difference between the two when it comes down to it, so the vinyl is the much better buy in my opinion. There’s no reason not to use the included uncoated cable for as long as it’s holding up, but I wouldn’t replace it with the same uncoated cable.

Again super sorry – very rarely miss a comment like this =/

Hey, no problem, am glad you replied at all haha. Thanks for the tip, I was planning on getting 1/4″ coated cables anyway.

I saw some sites offering nylon coating instead of vinyl coating, claiming the former is more abrasive resistant. Not sure if there is indeed a noticeable difference. Any tips on how to minimize the friction to maximize the lifetime of a cable? Not sure if there is a way to emulate commercial gym machine cables – they seem very sturdy and don’t give the impression of requiring semi-regular inspection and servicing. I’d imagine the size of the pulley (diameter) relative to the cable thickness would affect the friction (the bigger the ratio the less wear due to shear) since the cable runs over a less acute angle. Oiling is another good way to minimize friction, as well as using multiple pulleys to make cable running angles less severe.

Just tossing around some ideas, and wondering if you might have better tips. Thanks again, and no worries about the replies. Everyone has a life! Haha

I can’t speak to the nylon versus the vinyl, but the reason I say they are all wearable is because even the commercial machines can require cable replacements from time to time.

You’re right about the angle in that the Spud uses a very small pulley, and with only a single pulley it’s being put through more extreme angles. A lat pulldown machine doesn’t have any cables that exceed a 90 degree bend, and there is some space between each pulley. They’re metal cables, not belts. So I think no matter what a simple system like the Spud will wear a cable faster than a commercial machine with multiple pulleys, but I can promise vinyl will last longer than the crappy uncoated cable that as far as I know is still being included with the product.

If you try the nylon, keep an eye on it. I mean keep an eye on it anyway but really watch something that isn’t the norm, you know? Broken any cable = snap city haha.

When you order the cable from national gym supply doesn’t the cable come crimped from them? Would the cable end fit through the pulley?

You’ll have to disassemble the pulley to put it through. It’s super easy – just pull that pin and it’ll come apart. There are so few pieces that it’s not a challenge to put back together.

Instead or using wire rope, I got some spectra sailing rope. 3/8 spectra is rated to 13000lb and is designed to go around pulleys. Also just used pulleys from a yacht as well.

huh that’s not a bad idea. Thanks Scott

I also had a terrible warranty experience with Spud Inc. My pulley was defective and so I contacted Spud and the guy was friendly and seemed helpful and said he would send out a replacement. I waited a couple months and when I received nothing, I contacted them again. It took 4 tries to even get a reply, and then they said they would look into it and get back to me.

That was over a year ago and I have since tried contacting them at least 5 more times, and heard nothing. Can’t even get a reply from them. I have officially given up on Spud customer service and went and bought my own pulley. Once I received that, the system works great.

But it’s sad you buy a new product and then have to go buy a replacement for that product to make it work.

Just throwing this up so people are aware to not count on getting any warranty or after purchase service. But obviously this is only one persons experience.

I want to add the low pulley, but figure it’s probably better to make a diy version since I have no idea what I will get from Spud and may have to build my own anyway.

That’s disappointing to hear. Fortunately it is something that can be done DIY. A year though.. jeez that’s ridiculous

It should be noted the Spud Pulley kit is now $109.

From $85 to $99 to $109 in a couple years. Have we had 25% inflation at that time?

The cable appears to be nylon coated now and customized lengths are also offered. I got the triceps pulley about 3 years ago, but mine is in use only about 6 weeks a year at my outdoor summer cottage gym so no issues with the uncoated cable as of yet. I’ve been very happy with it too, heavy lying rows with feet braced against the rack on a bench are particularly good (hard to go much above bodyweight though). I find there is some degree of extra friction when you start going into the 4 wheel range but it still feels good.

Specifications:

– ¼” Nylon Coated Cable: 6’3” long (Custom cable lengths available for an additional fee. Please allow up to two weeks for fabrication of custom cables)

– 2.5” Swivel Eye Pulley

– Maximum Weight Capacity: 550lbs

Instagram seems to be full of other companies selling rip offs of the pulley now, no doubt fueled by the “Covid-19 home gym revolution”.